Award Statue

People sometimes give out awards so I wanted to make an award statue similar to those given out at the Oscars or Genies or other shows.

My logo image on my business card is a nice abstract figure. To turn my logo into an award statue I had to first turn it into a 3D model from which it could be printed.

I hired a service on Fiverr.com to convert my 2D logo image into a 3D shape. The first provider took my 2D image and simply thickened it into a 3D shape, much like a cutout, and returned this to me. I wasn’t satisfied with his work so I cancelled this contract and engaged a second provider. This person again returned a cutout but spent the time to consider my needs and provide a draft solution before committing to the work. This was satisfactory.

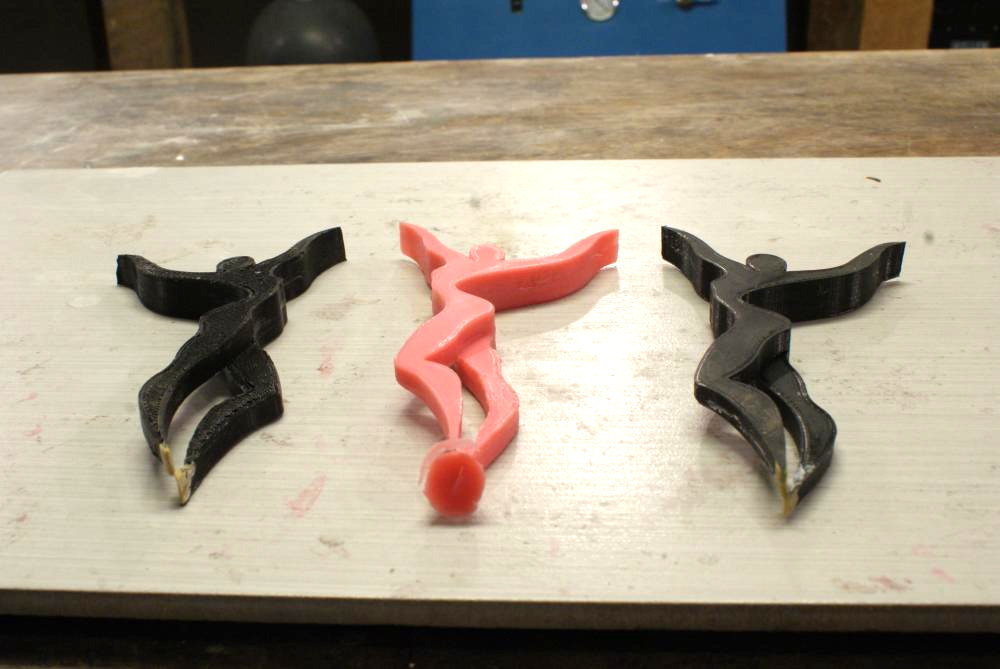

I used a local 3D printing service from AmorTech Design Labs to print the figure. The figure was scaled to be about 14.5 cm high which is the largest capacity of my 4×7 inch casting flask. I also made a silicone rubber mould of the printed figure so that I can replicate the statue in wax.

The next step is to cast the bronze statue and mount it on a base. I wanted to use a pedestal for the base and thought an aluminum manufactured base for a taper might work. I fabricated a wax fitting or plug sized to fit inside the holder so that I could cast a bronze fitting and solder the statue to this fitting.

The next step is casting. I cast the statue in silicon bronze and the fitting for the taper in yellow brass. The statue itself is 160 grams. The complete work on the aluminum base weighs 415 grams.

You can see shrinkage casting flaws in the picture above in the chest and groin area. I will be able to repair these, but it is always useful to minimize this type of work. This shows that I will need additional sprues into the casting to feed metal when I next cast these statues.

The final work when mounted on the pedestal should look similar to the picture below.

I’m not too sure about the aluminum pedestal? The glass one looks better, I think.

No comments yet.