Yan Wu 3

Now that I have cast the main body for Yan Wu it is time to create the flowing ribbons that descend from the back of the figure.

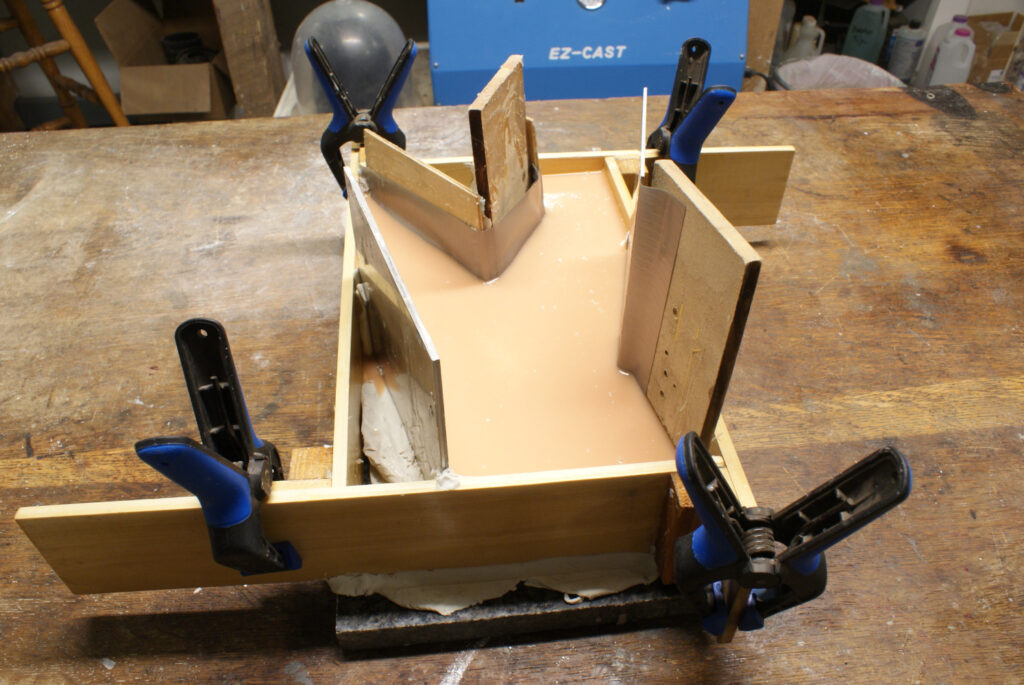

These parts are large. I struggled to decide how to economically mould and cast these pieces. I considered sand casting but in the end I decided to mould the parts in urethane rubber. This is a little less expensive than silicone rubber but not quite so durable.

I packed the pieces using a few pounds of modelling clay. It takes at least two hours or more to prepare the mould box. Each side of the two part mould used over 2 pounds of urethane rubber.

After the parts are replicated in wax they have to be cut down in size to fit into my casting flasks. Parts can typically fit into a 4×6 or 4×7 inch flask. Each part when cast requires about 400 grams of bronze.

Three parts are required to create the full set of ribbons across Yan Wu’s back. Each part has to be soldered to the back and to each other for structural strength. As these pieces are fairly massive it takes a fair bit of heat to to reach silver solder temperatures. The bronze needs to be at a dull red temperature. Both my regular acetylene air torch and my small ox-acetylene torch were used at the same time to braze the bronze parts.

The last step is to re-attach the ribbon ends that were cast separately as the pieces had to be cut to fit into my casting flasks.

This concludes the first layer of flowing ribbons on Yan Wu. There is a second layer fastened underneath that will be cast and assembled.

No comments yet.