Eureka Project – Wax Models

This post describes the creation of silicon rubber molds and wax models for bronze casting using the lost wax process.

The first step to create a bronze statue of Lemmy Miyauchi is to make silicon rubber molds of all the model parts. These molds will be injected with wax to create wax copies of the parts. The wax copies are then embedded in a silica plaster that when heated and hardened can be used as a mold for the molten bronze once the wax is melted out.

Lemmy Miyauchi

Lemmy Miyauchi

The silicon rubber that I am using for my rubber molds is Alumilite Quick Set silicon rubber. This rubber is mixed from two liquid sources. One source is the rubber and the second is a catalyst. The rubber cures in 8 hours and uses a 1:10 catalyst to rubber ratio by weight. The rubber is expensive. It is necessary to produce about 10 copies from each mold to achieve economies of scale.

Alumilite Quick Set

Alumilite Quick Set

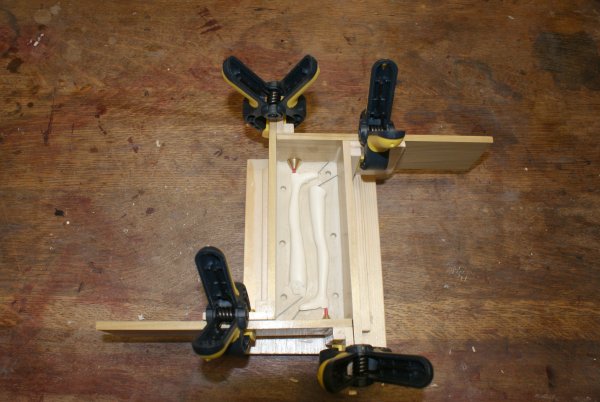

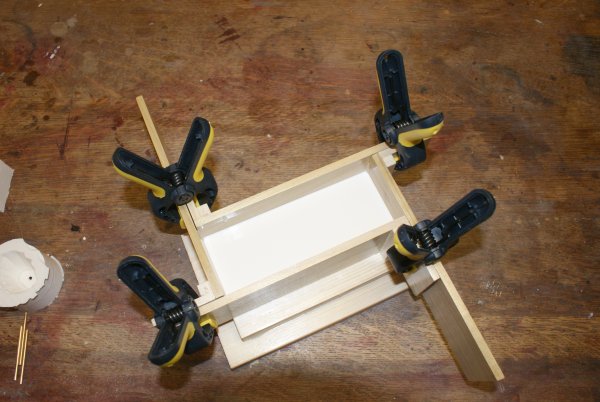

The rubber mold is made in two parts. The two parts allow the rubber to be separated so that the original piece can be removed. To create a two part mold a base is first constructed from modelling clay. The original part is then embedded in the clay. Air vents and an injector gate are added, along with positioning divots in the clay. The volume of rubber required for the mold is determined by filling the mold box with water. Once the water is removed the rubber is then measured and poured and chemically cures.

Silicon Rubber Mold

Silicon Rubber Mold

Silicon Rubber Mold

Silicon Rubber Mold

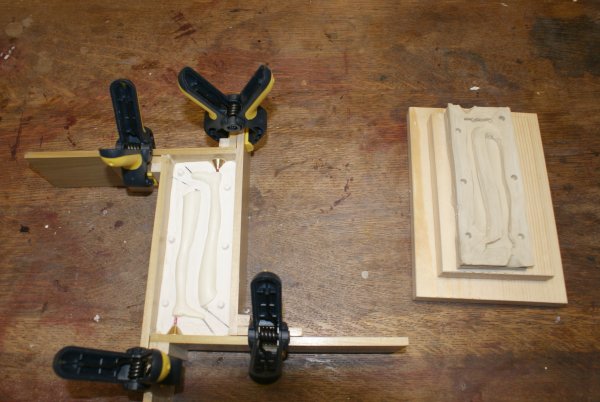

When the first part of the mold is cured it is inverted and the modelling clay is removed. The second part of the mold can now be poured into the mold box. A silicon rubber release compound must be sprayed or painted on the cured rubber to stop the second pour from adhering to the previously cured rubber.

Silicon Rubber Mold

Silicon Rubber Mold

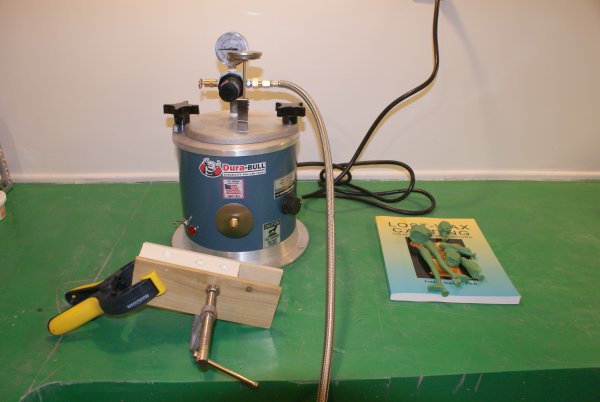

Once the rubber molds are created hot wax is injected into the mold. The wax is injected under 3 to 10 pounds of air pressure. This forces the liquid wax into the mold and expels air through the vents. After the wax has cooled and hardened the silicon rubber mold can be taken apart to obtain the wax models.

Wax Injector

Wax Injector

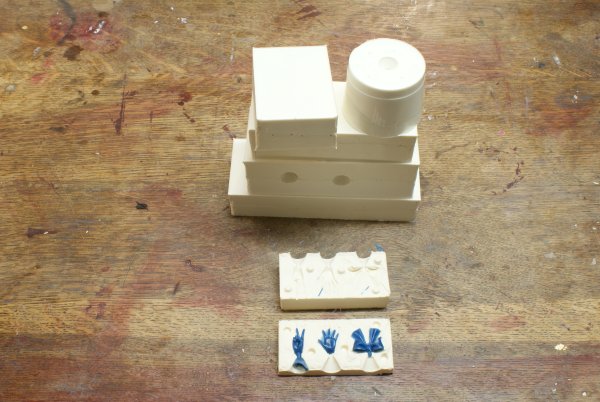

Wax Models

Wax Models

Silicon Rubber Molds

Silicon Rubber Molds

Wax Model

Wax Model

Once all the wax models are created a copy of the original figure can be created. This has been done only for demonstration. The figure will not be cast as one complete statue as my intention is to use different metals and patinas to separately color each part.

Wax Figure

Wax Figure

i can’t believe i’ve never thought of using water to measure how much silicone to mix!! haha

awesome information on this site!! the lost wax process is so interesting